Integral corners produced during the casting process further enhance the natural appearance of the façade. As openings were cast into panels, frames and doors were installed immediately, hastening the enclosure of the building’s perimeter.Īlthough the architectural skin was composed primarily of inset red-brown thin brick to resemble hand-laid brick while a contrasting white brick was chosen to offset the entrance. The slant position of the panels enabled the erector to use a single line crane and erect the steel and precast simultaneously. Casting, stripping, and field finishing are all performed at the casting facility so fabrication, shipping and erection may be completed in harsh winter conditions.

CarbonCast enclosures are an all-weather material manufactured in a plant. Under the auspices of the Department of Defense and the Defense Priorities and Allocations Systems Program, the project was given the highest priority and an accelerated schedule during January and February. This enabled eight-inch panels to satisfy blast requirements and maintain continuous insulation for an R-13 value, the minimum required by the Army Corps of Engineers.

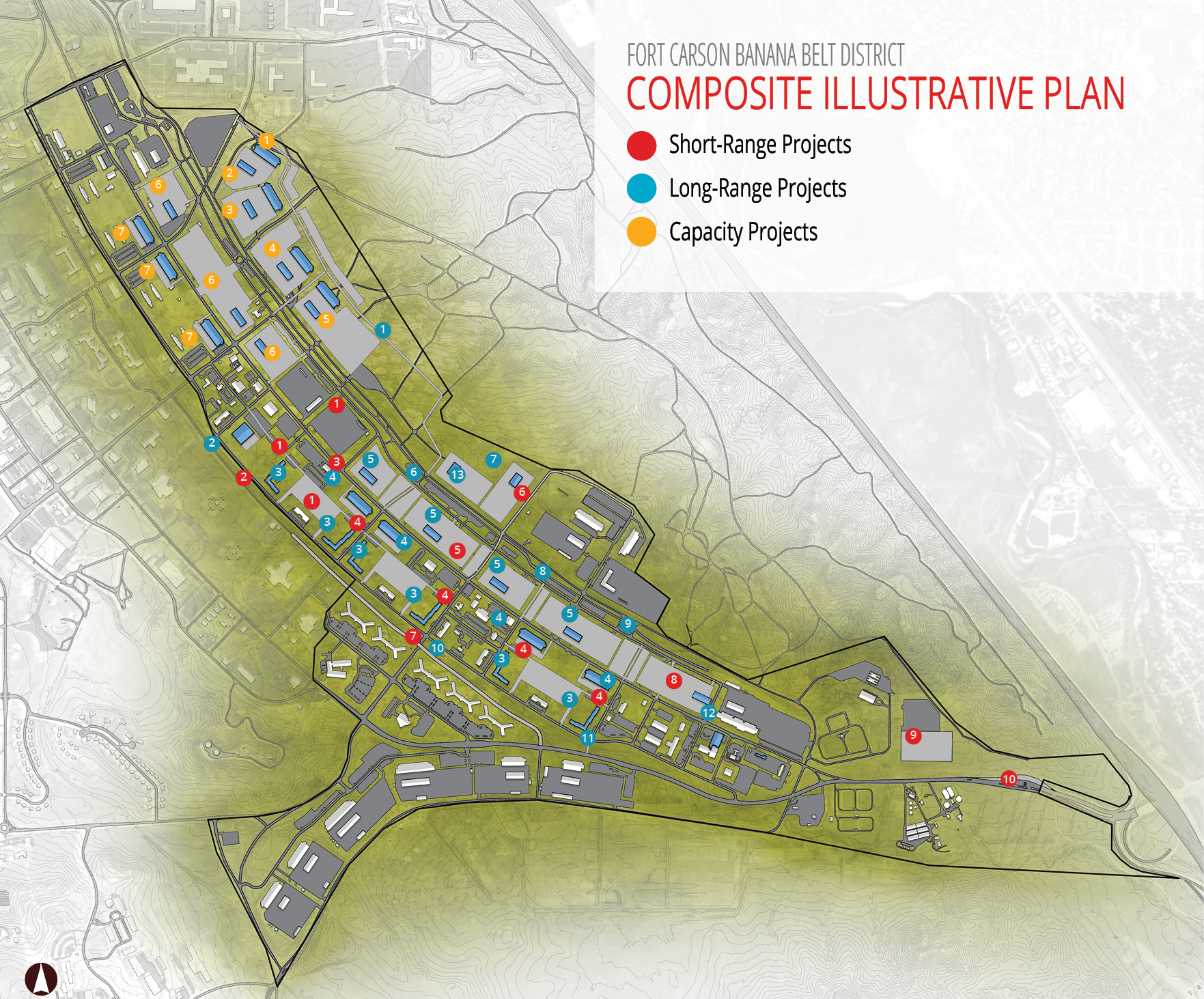

C-GRID is more than four times the tensile strength of steel by weight with negligible thermal conductivity. Original in its use of materials and completed on an accelerated schedule, the installation is a model of energy efficiency and design performance.Ī total of 57 insulated composite wall panels connected with C-GRID® epoxy-coated carbon fiber grid shear trusses were used to offset solid zones around windows, doors and top edges. The $35.6 million, 141,000-square-foot Fort Carson Brigade and Battalion Headquarters is a three-building military complex constructed with innovative CarbonCast® High Performance Insulated Wall Panels.

0 kommentar(er)

0 kommentar(er)